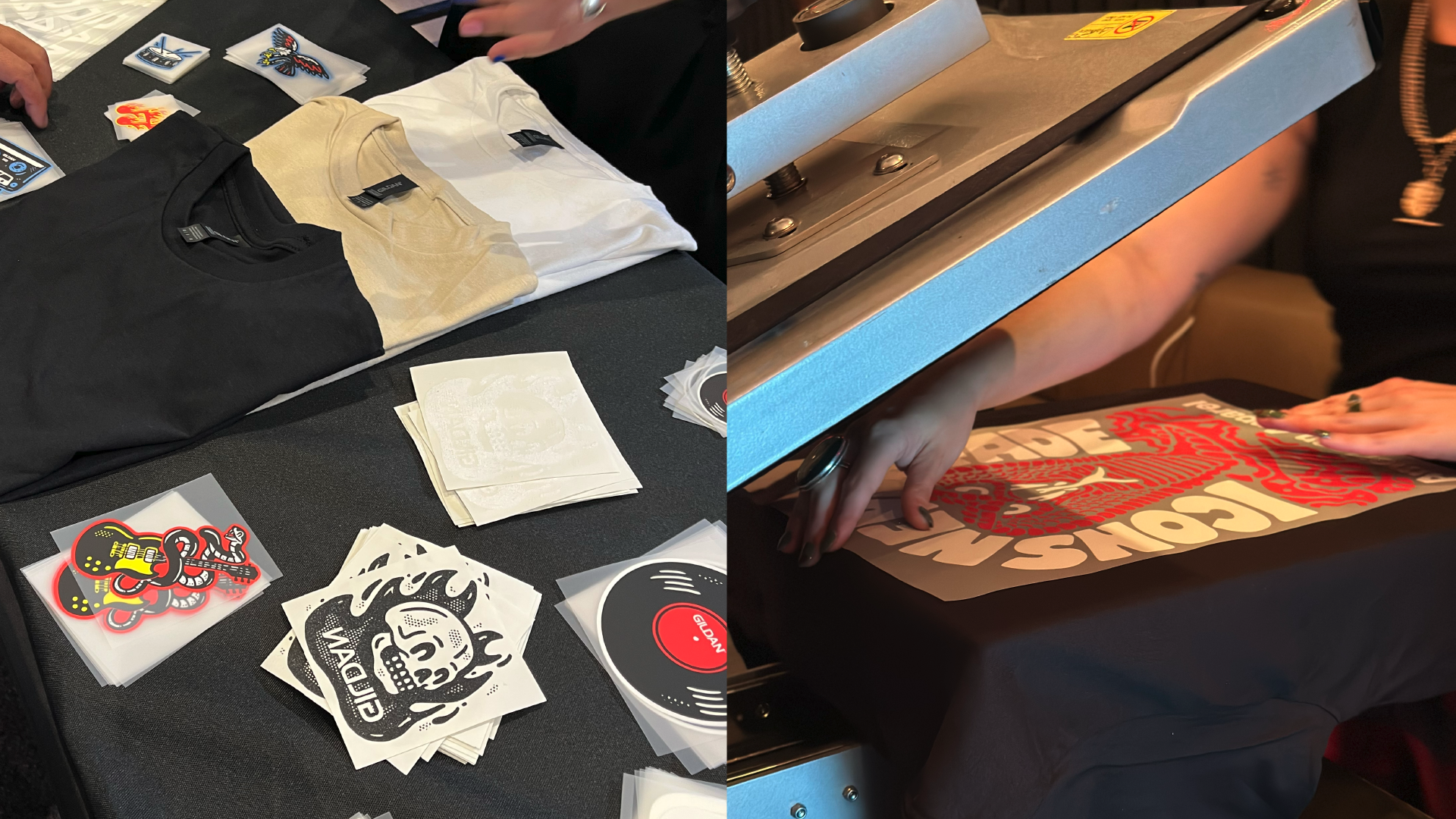

Printing Techniques 101: Screen Printing, DTG & Heat Transfer

Posted by Jaanvi Mittal on 15th Jul 2025

If you’re in the business of decorating apparel, knowing your print techniques isn’t just useful — it’s essential. Each method has its own strengths, quirks, and best-use scenarios. Get it right, and you’ll have a finished product that looks sharp, feels great, and stands up to repeat wear. Get it wrong, and you could be looking at disappointed customers (or costly remakes).

Here’s a straightforward breakdown of the big three: screen printing, direct-to-garment (DTG), and heat transfer, so you can pick the right tool for the job.

Screen Printing: The Classic Workhorse

Screen printing is the go-to for most decorators. It uses mesh screens and ink pushed through by a squeegee to lay down each colour.

Best for:

-

Bulk orders (20+ units) — because once your screens are set up, printing is fast and cost-effective.

-

Simple to mid-level designs (think logos, text, bold graphics).

-

Long-lasting prints that stand up to wash after wash.

Considerations:

-

Not ideal for complex full-colour images or small runs (screen setup takes time and money).

-

Requires proper curing to prevent cracking.

Pairs perfectly with:

-

Gildan Softstyle® 64000: smooth, ring-spun surface for crisp edges.

-

American Apparel® 2001: ideal for detailed halftones or fine line work.

-

Comfort Colors® 1717: loves water-based or discharge inks for that vintage, worn-in vibe.

DTG: Direct-to-Garment Printing

DTG is essentially a giant inkjet printer for textiles. It sprays water-based inks directly onto the shirt, great for photorealistic designs and low quantities.

Best for:

-

Small runs, one-offs, samples, or personalisation.

-

Intricate, full-colour images (like photographs or multi-shade art).

Considerations:

-

Needs high-cotton content for best results.

-

Doesn’t always pop on dark garments without a white underbase (which can change the hand feel).

-

Slower per piece than screen printing.

Best blanks:

-

High % cotton, tight weave.

-

American Apparel® 2001 is a top choice for detail and softness.

Heat Transfer: Flexible & Fast

This method uses printed transfers (vinyl or digital), which are applied with heat and pressure. Great for adding names, numbers, or graphics on demand.

Best for:

-

Custom jobs like sports kits, corporate uniforms, or special event shirts.

-

Low volume or quick-turn projects.

Considerations:

-

Transfers can crack or peel if applied poorly or washed hot.

-

Less breathable feel under large designs.

Works well with:

-

Most smooth cotton or poly-cotton tees, like the Gildan Softstyle® or American Apparel® ranges.

So, Which Technique Should You Use?

It’s all about your priorities.

-

Need volume and low cost? Screen printing.

-

Want to showcase complex art in small runs? DTG.

-

Doing personalisation or short-run names & logos? Heat transfer.

At the end of the day, the smartest decorators match their technique to the job — and pick the right blank to support it. That’s how you end up with prints that look sharp on day one and still turn heads after ten washes.

Need blanks that play well with all three?

Check out Gildan Brands AU — local stock of Gildan, American Apparel and Comfort Colors means faster turnarounds, consistent quality, and blanks built for your press.